IMS Technologies

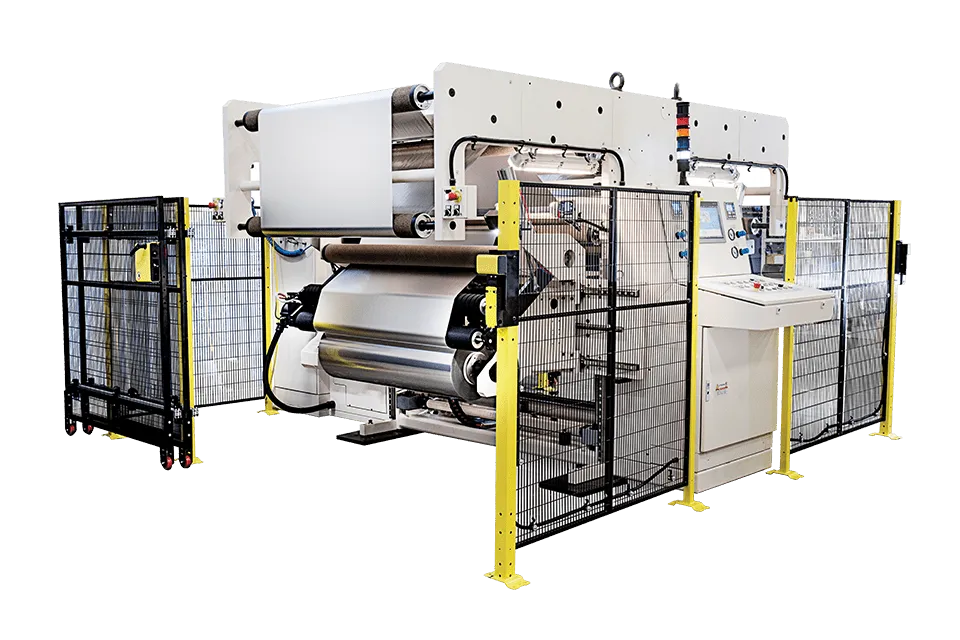

Discover cutting-edge slitter rewinders designed for the flexible packaging industry at LAEM IMS. Our high-tech slitters are renowned for processing and slitting a diverse range of materials, with a special emphasis on all types of flexible packaging.

LAEM IMS slitter rewinders are tailored to handle even the most delicate, complicated, structured, and innovative materials, ensuring we meet our customer’s unique needs. Our commitment to perfect web handling technology and precision slitting is evident throughout the rewind cycle, thanks to advanced automations in the rewind area.

Our portfolio of slitter rewinders includes different types of machines catering to the different needs of our customers:

- DUAL SHAFT SLITTER REWINDERS: discover our dual shaft solutions designed to rewind and produce high quality finished reels with large diameters. Thanks to the dual slitting method – razor blades or circular knives – these machines are able to process almost any type of flexible packaging material with various thicknesses.

- TURRET SLITTER REWINDERS: explore LAEM IMS turret slitter rewinders aimed at reaching high production speed. The automatic change-over of the turret system ensures a drastic reduction of machines downtimes.

- STATION SLITTER REWINDERS: our station solutions are designed to keep an optimal tension control of the web thanks to the center-driven or center-peripheral rewinding technology and to produce high dimension finished reels.

- OTHER TECHNOLOGIES: delve into our additional technologies created to process specific applications, fusing advances in digital control technology with the proven winding process features of LAEM IMS slitters.

Relying on its bold know-how, LAEM IMS has pioneered a technology that serves as a targeted solution highly esteemed by industry leaders. Our versatile machinery is at the forefront of innovation, constantly adapting to the newest technologies and flexible packaging materials.

Ensure high quality finished reels thanks to LAEM IMS doctoring machines

What is a doctoring machine?

A doctoring machine is an inspection rewinder that – thanks to process monitoring – can recover bad reels or perform a post production quality check. This allows operators and producers to ensure high-quality standards.

Thanks to its extended know-how, LAEM IMS has developed doctoring rewinding machines for flexible packaging materials. Our doctoring machines are especially designed to eliminate incorrect printed spans with means of high technology control on web misalignment.

Nevertheless, they are customised to each and every need of a process or of a factory, ensuring four main benefits:

- Perfect production quality;

- Material waste reduction;

- Recover of alignment defects;

- Correction of prining mistakes thanks to the splicing tables.

Discover LAEM IMS’ doctoring machines for flexible packaging materials

Our portfolio includes three doctoring machine models:

- VIS 100 mono and bidirectional doctoring machine for wide reels

- VIS 60 mono and bidirectional doctoring machine for medium reels

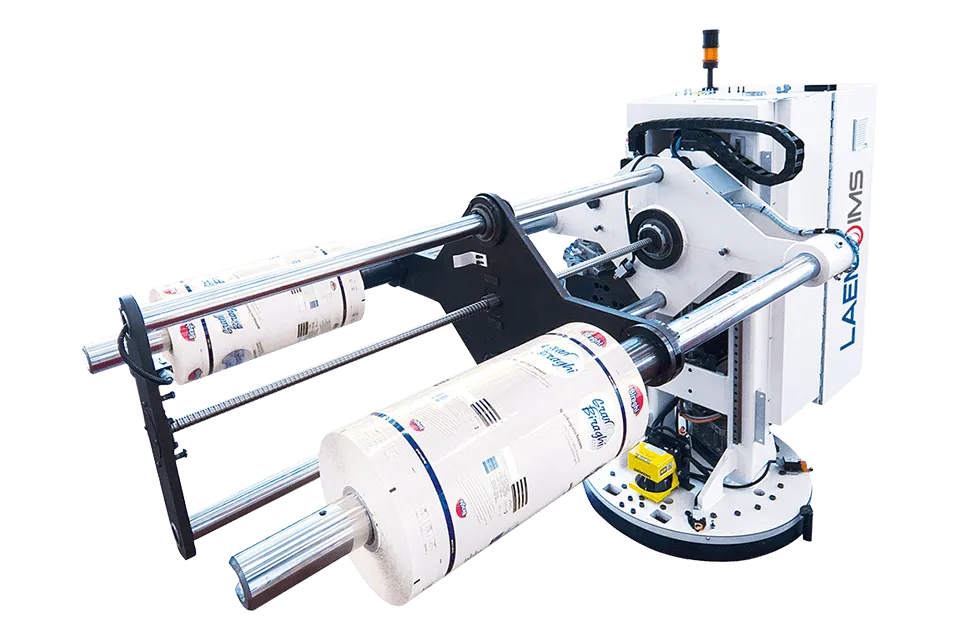

LAEM IMS comprehensive range of unloading tools and robots enables any company to match their production habits with the machine final output point. We offer manual, semi-automatic, fully automatic unloaders up to robotised packaging gantries.

Further accessories include the possibility of loading cores, setting and changing slitting/rewinding patterns and tabbing the reels on or off the machine. Ergonomy and utmost safety are keys to engineer our equipment to be used by workmanship or robot alike.

A core cutter is the convenient accessory for companies that want all cutters from a Manufacturer that stays on the technology cutting edge.