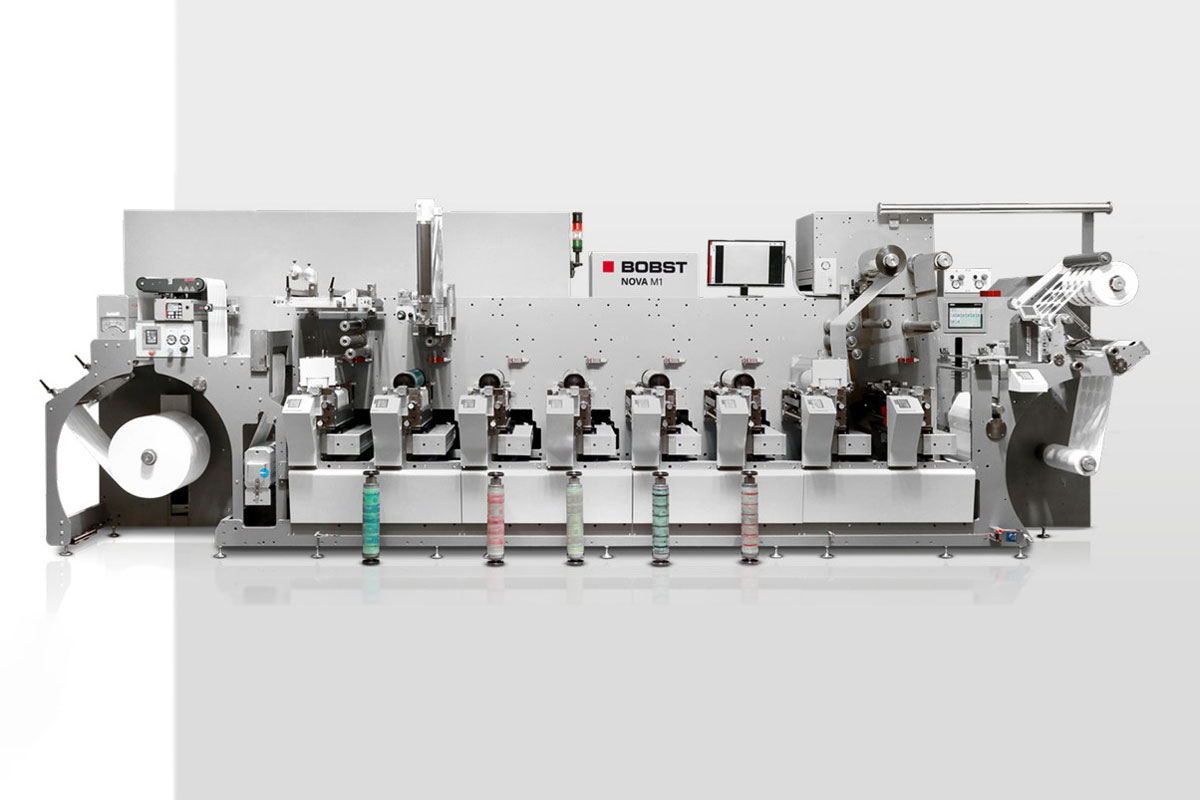

Narrow Mid Web

Reliable performance

- Flower flexo head for easy and fast job changeovers

- Intuitive and easy to use for unskilled operators. Touch panel on each print unit and main HMI.

- Very short set-up time

- High uptime, fast time-to-market

- Max 8 colors. 1 die-cutting unit.

Minimum waste

- Very short web path

- Very short set-up waste

- Excellent register accuracy

- Automation ensuring productivity and process repeatability.

Increased productivity at lower costs

- Printing and converting in one pass

- Low energy consumption

- Low maintenance and running costs.

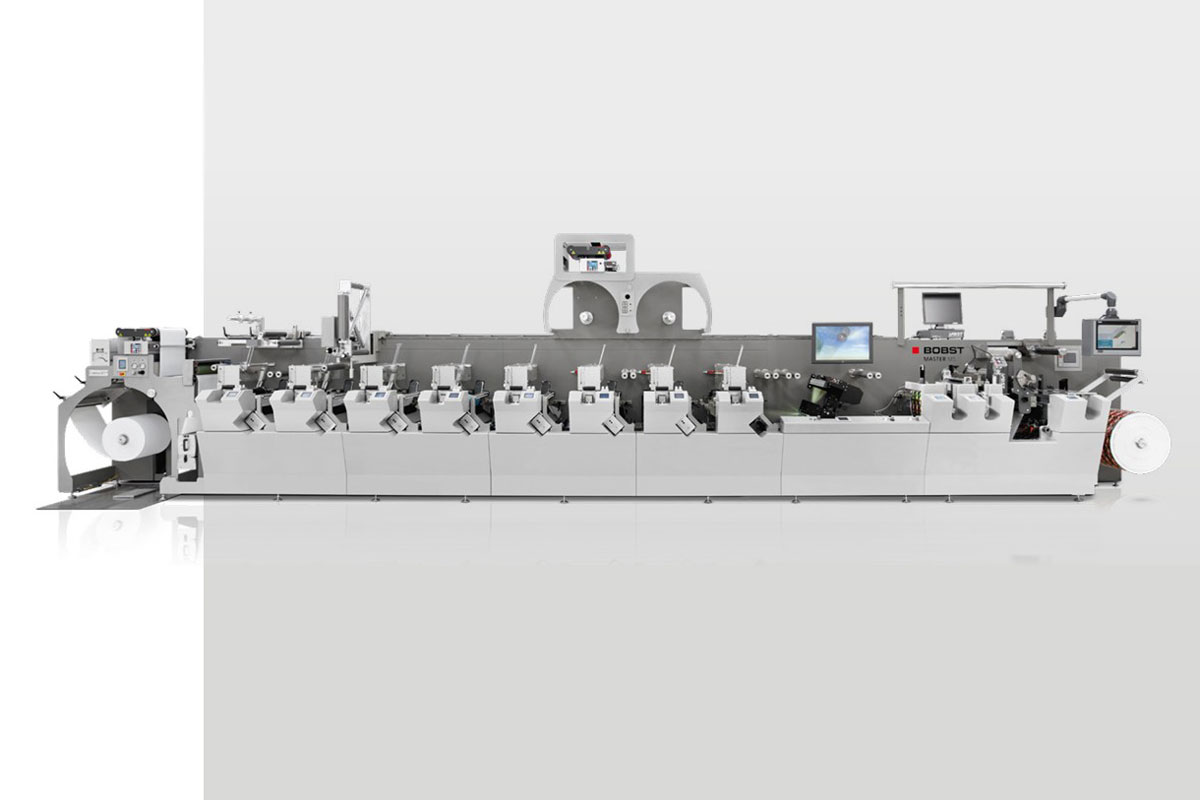

Exclusive innovations for unrivalled performance

- Minimum waste of substrate and consumables at start-up and job changes with smartGPS or smartSET exclusive systems for registration and impression setting

- smartFLO inking system and chamber doctor blade delivering predictable, stable and controlled printing results with all ink types

- triLOCK bearing system with high torque mechanism replacing manual locking

- Full Surface Matrix intercolor dryer preventing substrate stretching

- oneECG for optimized results with 7-color ECG process

- Hybrid, dual technology tunnel. Energy saving due to efficient drive system and ventilation

- Fully automatic bi-directional reel splice at machine production speed. Winders’ energy recovery solution

- Compact footprint with face-to-face winders.

Exceptional printing flexibility

- Select from 4 printing systems:

- Solvent-based printing

- Water based printing

- E-beam printing

- Extended Color Gamut printing (ECG)

- smartGPS off-line fully automatic system for registration and impression setting or smartSET-press semi-automatic set-up system

- Modular extendable configuration of the drying tunnel

- Customizable for specific product requirements – downstream flexo units, gravure printing units and turning bars for reverse printing.

Connected and automated for maximum uptime

- Accurate process automation for minimized waste, increased cost efficiency and easy manufacturing

- Connectivity features to enable access to production data from remote services

- IoT including Predictive Maintenance empowering the operator to change wear parts before they fail.

Outstanding productivity – oneECG-ready

- Digital workflow with integrated printing and converting technologies enable 1 minute job changes, very high quality consistency at very low operating costs

- Unlimited substrate types

- High press uptime, very fast time-to-market

- Infinite Flower print unit for controlling print density changes at speed variations, monitoring ink temperature

- Multi-process, product enhancing inline finishing applications.

Precision and quality consistency

- Very accurate web-tension control from unwinder to rewinder

- Automatic pre-register setting

- ARC automatic print-to-cylinder register control.

More uptime, top efficiency

- Digital automation ensuring productivity and process repeatability

- Very short set-up time and waste

- Easy to run for less experienced operators

- Production data accessible from remote devices

- Connectivity features for informed decision making.

All run lengths, all applications, all industries

- The press handles all types of substrates used to produce labels, flexible packaging or folding carton

- Multi-process, product enhancing and inline finishing applications

- Outstanding print quality and color consistency and repeatability.

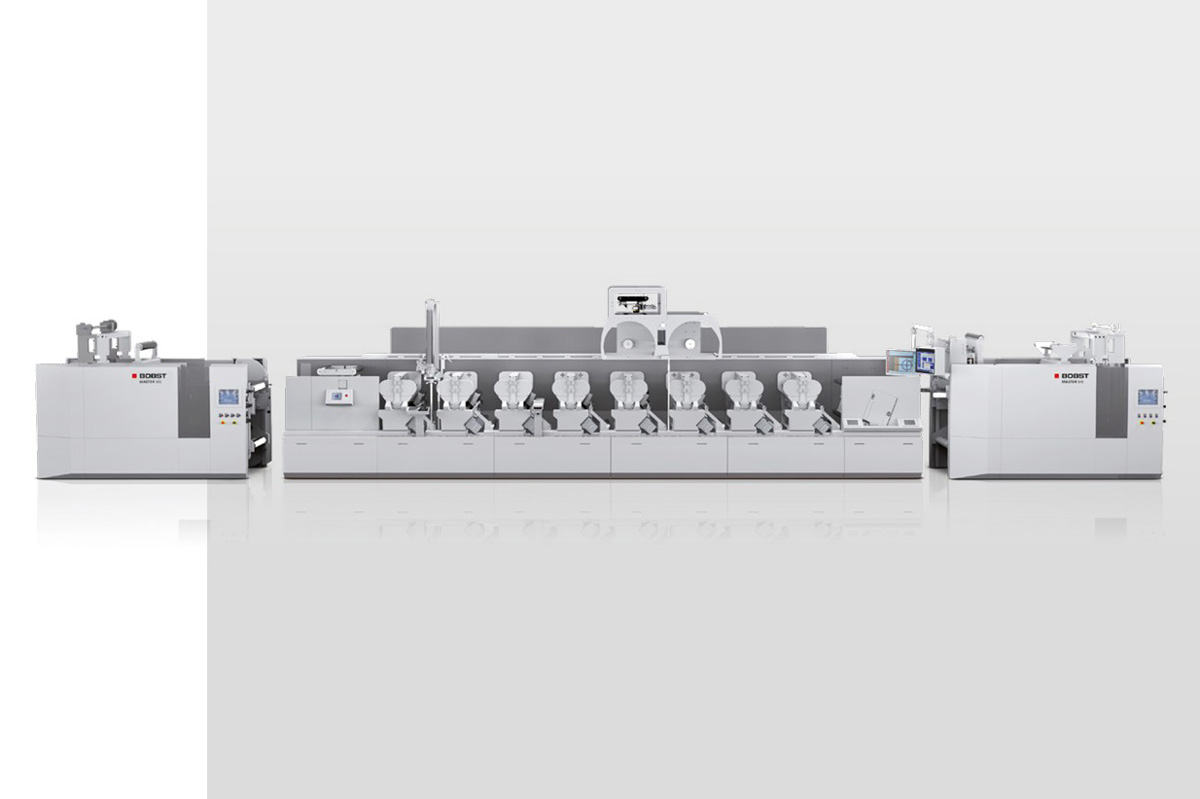

Highly productive

- DigiFlexo for full digital registration and pressure controls

- Very short set-up time and waste

- Excellence solutions for automatic exchange of printing cylinders and of die-cutting stations without stopping the press

Outstanding solution for food packaging

- Exclusive total traceability system for food packaging applications with UV Track. The UV emission is monitored while the press is running with certification of the whole printing process. This opens new opportunities for UV printed food packaging production.