Flatbed Die Cutters

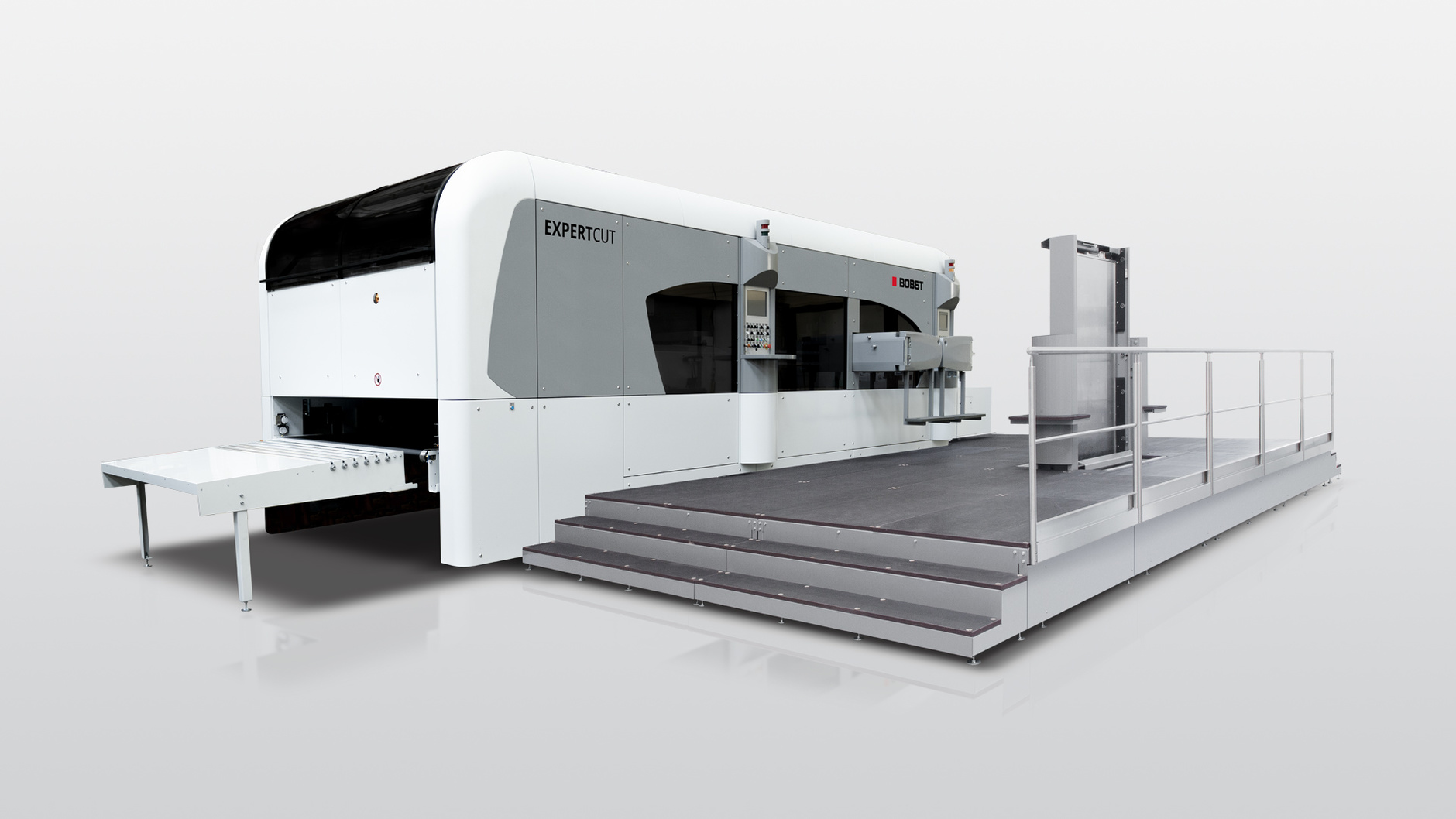

Cost-efficient, versatile and accurate

Lowest combined ownership cost of any machine in its class

Handles all types of materials

First-class die-cutting

Straightforward handling

Uncomplicated and easy to set up

User-friendly interface

Enduring power and efficiency

Optimized workflow for maximum uptime

Robust and long-lasting

BOBST service network and spare-part availability

Exceptional precision

Smoothest sheet transport and outstandingly precise cutting precision

Perfect stripping, waste removal and batch alignment for impeccable blanks

Impressive production rate

Fast changeovers for more uptime

Can be completed with flexo post-printing press and peripherals to create a full production line

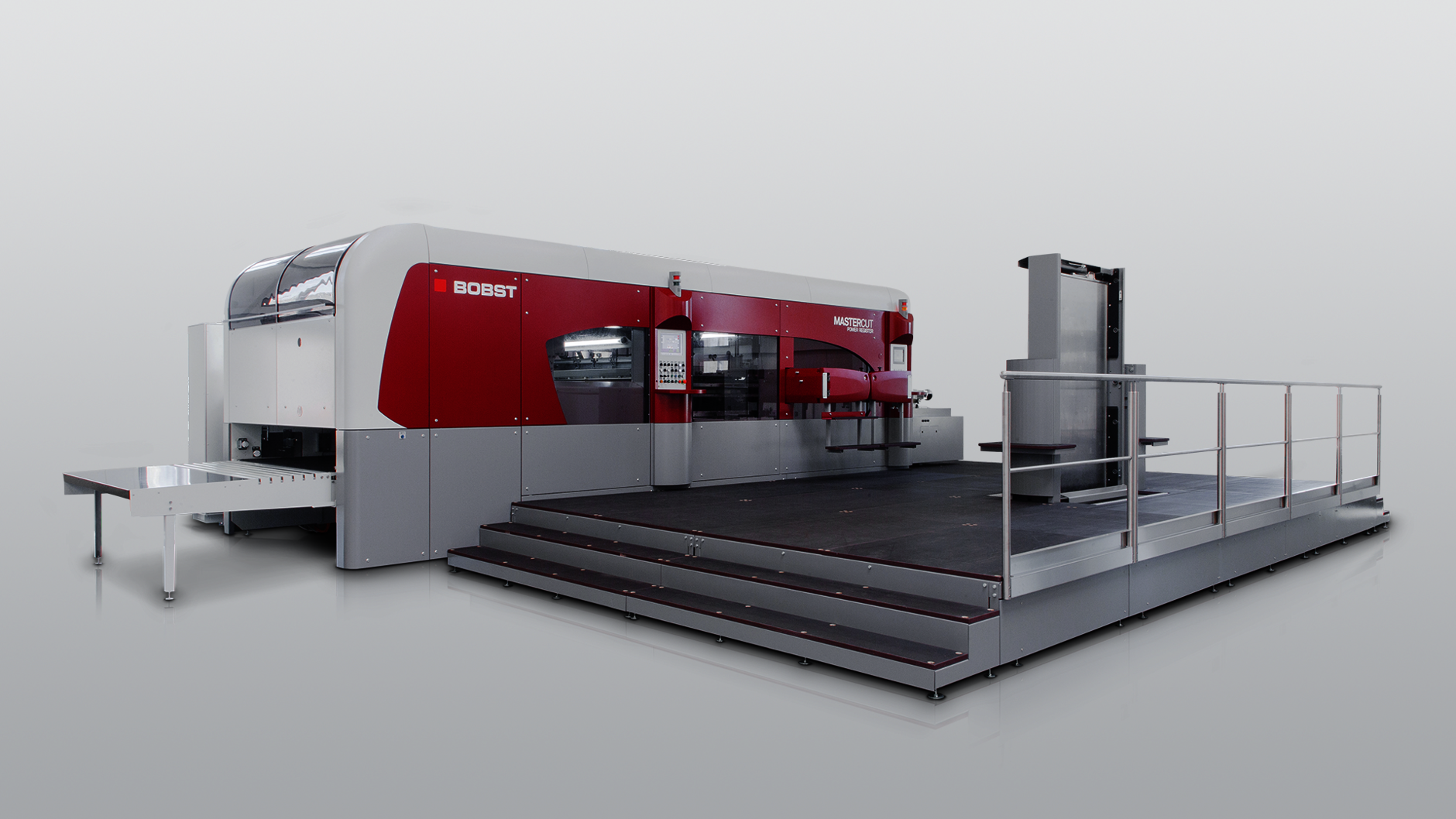

Robust, but flexible

Long-lasting, high-quality construction

Handles a large range of materials

Ideal for long and short runs

Exceptional precision

Extremely precise cutting precision and agile sheet transport

Perfect stripping, waste removal and batch alignment for impeccable blanks

Impressive production rate

Up to 6,000 sheets/hour

Nimble changeovers for more uptime

Possibility of full production line, including fully automatic loading, flexo post-printing, precise stacking and palletizing

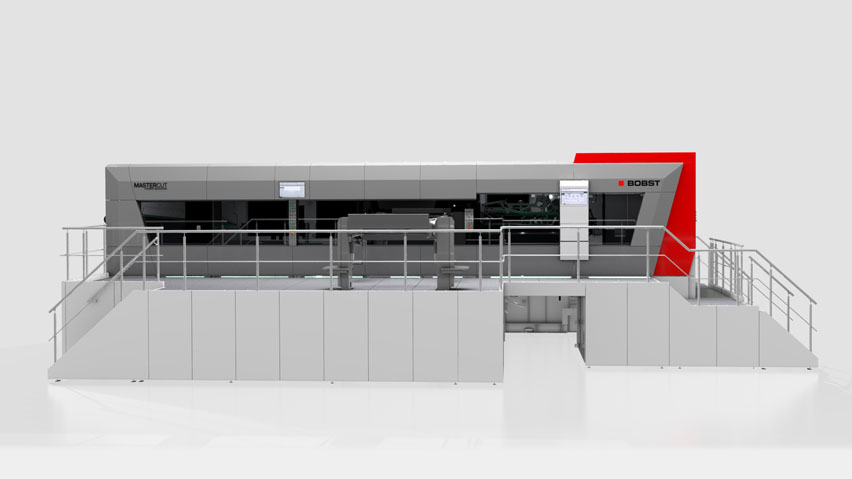

Robust, but flexible

Long-lasting, high-end quality

Capable of handling a large range of materials

Excellent for long and short runs

Unique litho-lam die-cutting

The only machine especially designed for litho-lam converting

Bespoke sheet-per-sheet top feeder for delicate and sensitive substrates

From 0.5 mm to 7.0 mm litho-laminated or corrugated board

The only solution in the market for blanking in size VII

One machine for all jobs

Complete flexibility: handles carton, corrugated board and litho-lam

Ultimate feeding table with dedicated pressing device and contactless register, handling robust and delicate materials equally well

Single, double cut blanking and full sheet delivery

High cutting force for multi outs and complex box designs

Amazing quality – in every way

Cut-to-print register and gripper bar locking for extremely precise die-cutting

Unique feeder without any frictions, guaranteeing scratch-free blanks BOBST flatbed die-cutting technology, for powerful cutting-force with low pressure on the substrate

Robust and long-lasting machine and high-quality tooling

Exceptional ergonomics with maximum level of automation and accessibility, intuitive HMI and IOT ready

Turning speed into profit

Up to 7,500 sheets/hour

Job changeovers in 5 minutes

Possibility of full production line, including fully automatic loading, flexo post-printing, precise stacking and palletizing

Reliable and easy to operate

Highly automated and MATIC

HMI with setting and display of all production parameters and job data storage

Unrivalled blank quality

Perfect sheet registration

Reduced contact and smooth transport, preserving sheet integrity