Erhardt+Leimer

Your Advantages

- Reduced paper waste

- Reduced trimming / max. width utilization

- Increase in productivity in corrugated cardboard production

- Improved quality of the finished cardboard boxes

Description

The CorrAligner Bridge Guiding System enhances corrugator productivity and the quality of the corrugated board as a result of continuously guiding the single faced webs to the position of the outer liner without the need to reduce production speed, for alignment purposes, during a wet-end grade or width change.

Depending on available space, the CorrAligner can be configured with a CorrGuide Outer Liner Guiding System or an Outer Liner Detection Unit both of which ensure that the correct conditions are created for minimum trim / maximum deckle utilisation at the Slitter Scorer.

Your Advantages

- Paper cost savings

- Simultaneous processing of two pre-print orders

- ELTrac function for standard production

Description

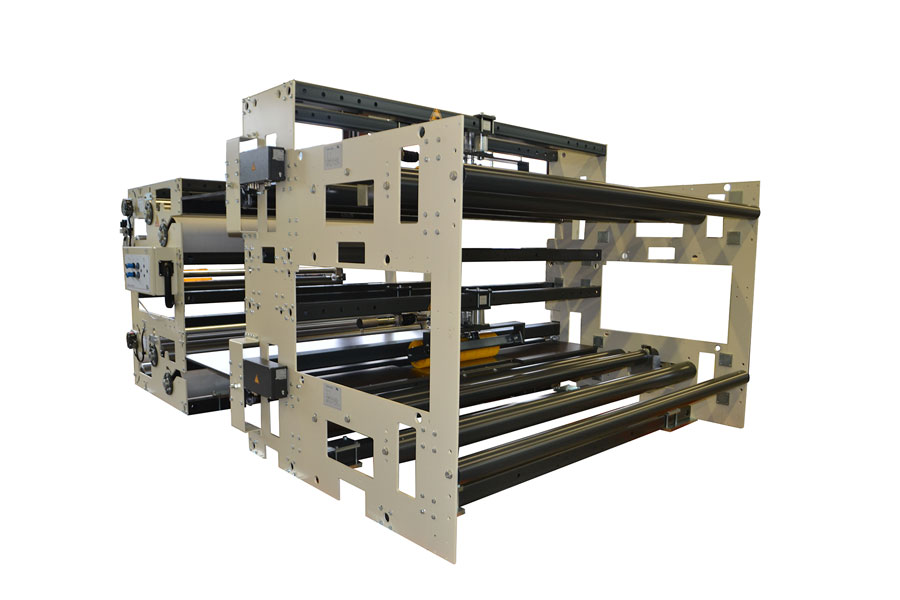

The SplitWeb Dual Guiding System gives the opportunity to increase the productivity of the corrugator through two different scenarios, both of which are a result of creating a full width paper from two narrow paper widths.

Firstly, if integrated into the outer liner, the SplitWeb Dual Guiding System enables customers to run two narrow pre-print orders at the same time, dramati cally increasing the productivity as a result of greater width utilisation of the corrugator.

Secondly, the SplitWeb Dual Guiding System enables customers to create a full width paper from low cost narrow reels, often referred to as side run tonnage. The SplitWeb Dual Guiding System can be integrated into the fl ute paper or liner paper paths.

Depending on installation location, the SplitWeb Dual Guiding System has the added benefi t of functioning as a CorrGuide Outer Liner Guiding System or an ELTrac Flute or Liner Paper Guiding Unit for standard width production.

In all cases, the SplitWeb Dual Guiding System requires that the corresponding reel stands are equipped with a central arm. Reel stand suppliers have the option to supply a new reel stand equipped with a centre arm or to supply a centre arm retrofit. The final scope of any additionally required equipment is dependent on the location of the SplitWeb Dual Guiding System and the confi guration of the corrugating machine at that point.

Your Advantages

- Automatic pre-print detection

- Minimal trimming

- Reduced waste

Description

The TrimMaster Slitter Scorer Guiding System is the key to enabling the slitter scorer to run with minimum side trim. The TrimMaster includes a Web Stabilisation Device which ensures that the side trim width is constant, which allows it to be reduced to the minimum width. In the case of pre-print production, the function and performance of the TrimMaster ensures that the required slit to print accuracy is constantly achieved.

The TrimMaster also contributes to reducing the overall paper waste as a result of eradicating the ‘tail-out’ waste which is created every time the rotary shear is used.