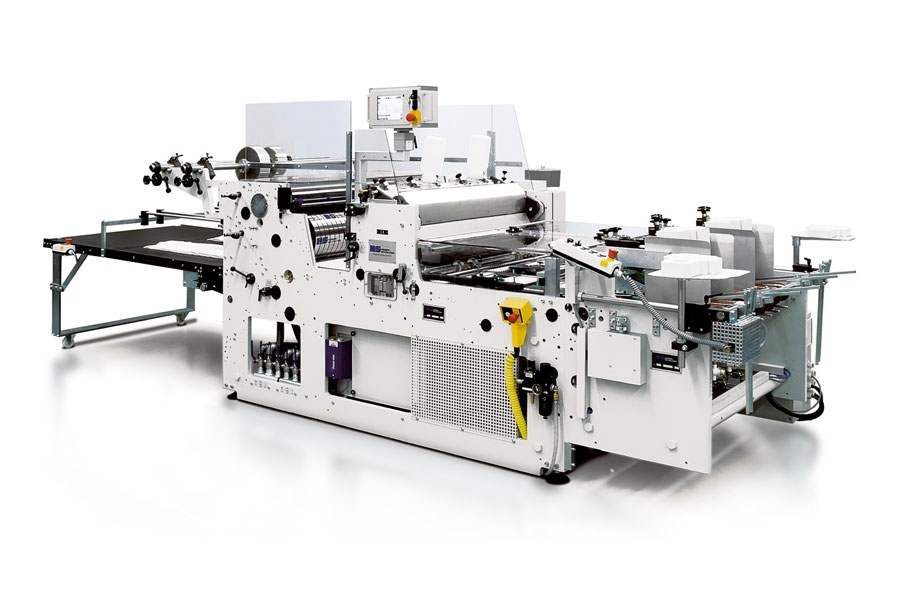

Window Patching

SOLID OUTPUT

- Up to 36,000 blanks per hour at ideal use of space (1 lane production)

REDUCED DOWNTIME AND INCREASED PRODUCTIVITY

- Patented feeder teach-in function and electronic friction control

PRECISION

- Outstanding foil/liner positioning due to an improved blank transfer system

STABLE AND ROBUST

- Heavy duty cross cutting system, smoother foil/liner cutting with less jam risk

LIFETIME DURABILITY

BEST-IN-CLASS SERVICE AND SUPPORT

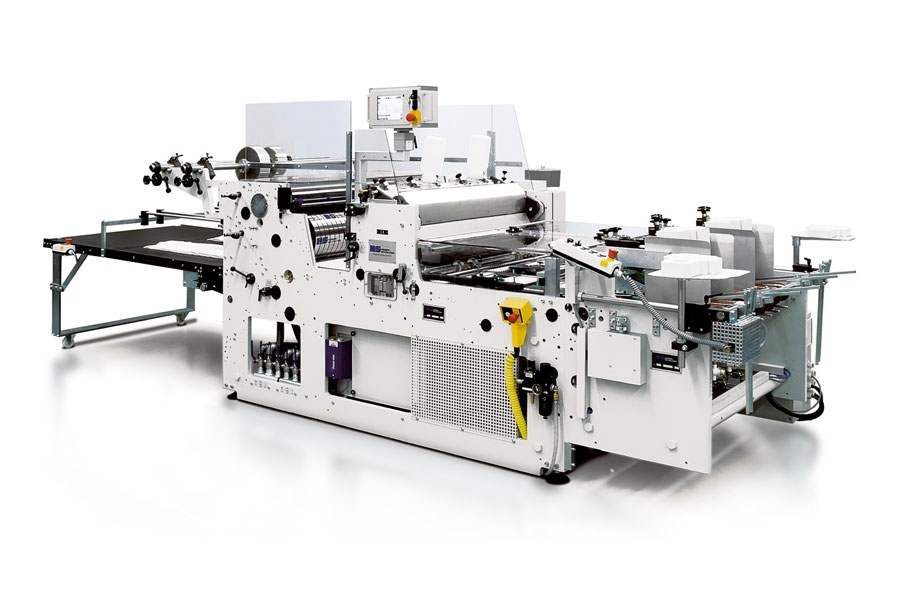

SOLID OUTPUT

● Up to 72,000 blanks per hour (2 lane production)

● Smooth operation even for film material with critical static load through high performance static discharge system

REDUCED DOWNTIME AND INCREASED PRODUCTIVITY

● Gluing unit with full splash guard and 2-minute integrated cleansing system

● Excellent flatness of the blanks (even when curved) thanks to patented mono-suction belt

● Best application tolerance for the film, both in running and lateral direction

● Maintenance-free air suction system, (no vacuum channels or filters)

● Standstill times for reel change can be eliminated by a patented H+S splicer system (option), constant web tension during operation and reel change is provided by automatically controlled brakes and dancer rollers

PRECISION

● Outstanding foil/liner positioning due to an improved blank transfer system

STABLE AND ROBUST

● Heavy duty cross cutting system, smoother foil/liner cutting with less jam risk

QUICK AND EASY SET-UP

● Electronically controlled time belt feeder series, automatic compensation of the feeder timing in case of changing friction or belt wear, feeding length adjustment via teach-in-button with only one single blank

● Film length adjustment via digital input, and during machine operation

● Automatic position alignment of cutting cylinders, suction cylinder in case of cycle change of film length reduces set-up times, defined machine stop position avoids operation errors and reduces standstill times

USER AND MATERIAL FRIENDLY

● Chemically nickel-plated, tooled steel inserts for suction holes (optional), cleanser-resistant, minimal wear, minimal risk of scratches on the film

● Laterally movable delivery ensures better ergonomics when mounting heavy film reels or working on the cutting station

● Intelligent adjustment-free jam monitoring at the chain station, safe and time saving

LIFETIME DURABILITY

BEST-IN-CLASS SERVICE AND SUPPORT

OPERATING PANEL

- Picture supported library for repeat orders

- Production statistics and, optional, production data acquisition

- Picture supported error messages

- Picture supported help system

- Modem connection for service and updates

- Automatic maintenance alerts

MINIMAL WEAR AND REDUCED MAINTENANCE EFFORT

- Chemically nickel-plated suction cylinder, tooled steel inserts for suction holes, cleanser-resistant, minimal risk of scratches on the film

- Latest generation drive technology: servo motors drive all rotating elements and are power consumption-optimized and maintenance-free

REDUCED DOWNTIME AND INCREASED PRODUCTIVITY

- Excellent flatness of the blanks (even when curved) thanks to patented mono-suction belt

- Gluing unit with full splash guard and 2-minute integrated cleansing system

- Standstill times for reel change can be eliminated by a patented H+S splicer system (option), constant web tension during operation and reel change is provided by automatically controlled brakes and dancer rollers

MASTER FEEDER

- Up to 4 different run modes

- Ideal feeding technology for each blank form and each type of material

- Electronically controlled, with lifter-free timing and automatic self-monitoring

- Feeding length adjustment via Teach-In button