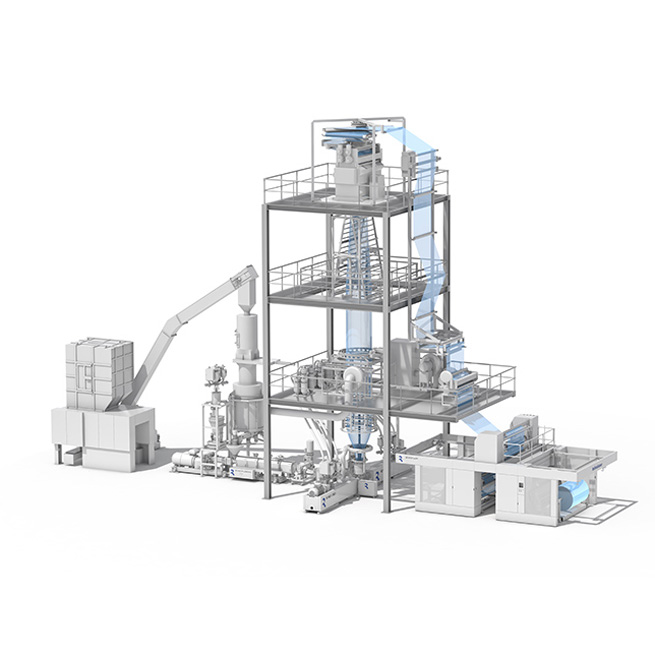

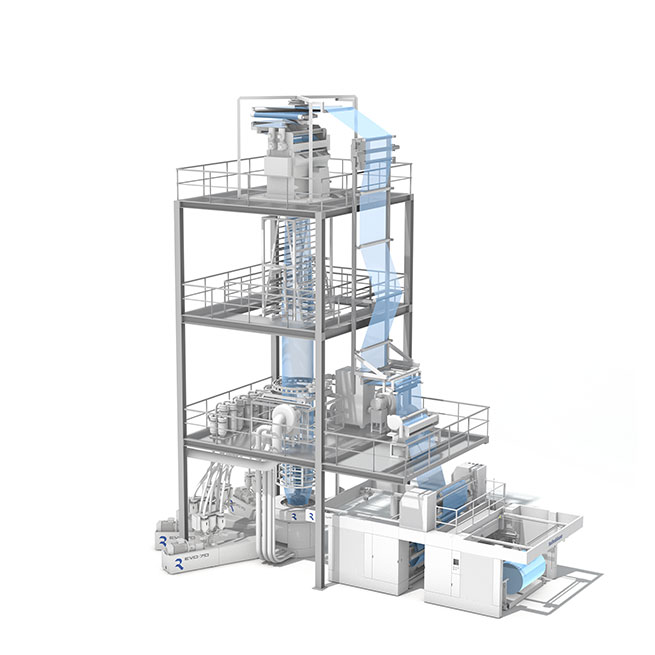

Blown Film Lines

Direct processing of 100% recycling material.

Circular Economy in perfection: Processing plastic waste into new film without energy and cost intensive pelletizing.

Processing recyclate

- 100% recycled material and barrier films up to 30% PA

Processing biomaterial

- Particularly profitable thanks to inline compounding

Save material

- Through inline dosing of high filler content

Save energy

- Thanks to direct extrusion without pelletizing and pre-drying

Flexible film production at high quality and cost-efficiency.

Flexible, reliable and future-proof: Our EVO standard lines cover an enormous range of raw materials and applications and can be adapted to special applications at the same time.

EVO: Perfect for you if you

- want to react flexibly to different market needs.

- need to switch quickly between different applications.

- want to produce highest quality economically.

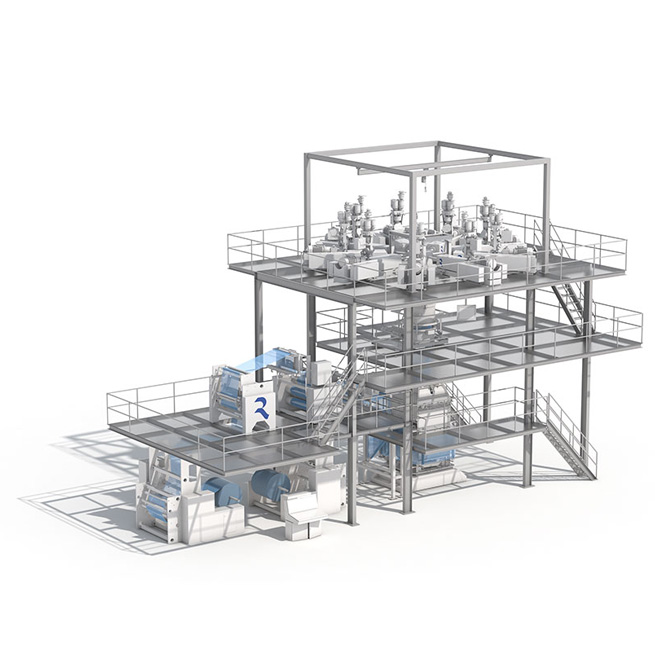

High-tech lines in a modular system

Thanks to the modular system, we adapt each production line to the customer’s specific needs. A wide range of extruders, winders, cooling systems, haul-off units etc. is available for this purpose. For products with particularly high quality requirements, choose components from our EVO Ultra series.

Our EVO series is also equipped with state-of-the-art IoT interfaces and can be seamlessly integrated into an “Industry 4.0” production environment. This allows you to automate your processes and have full access to current production data and the condition of your equipment at all times.

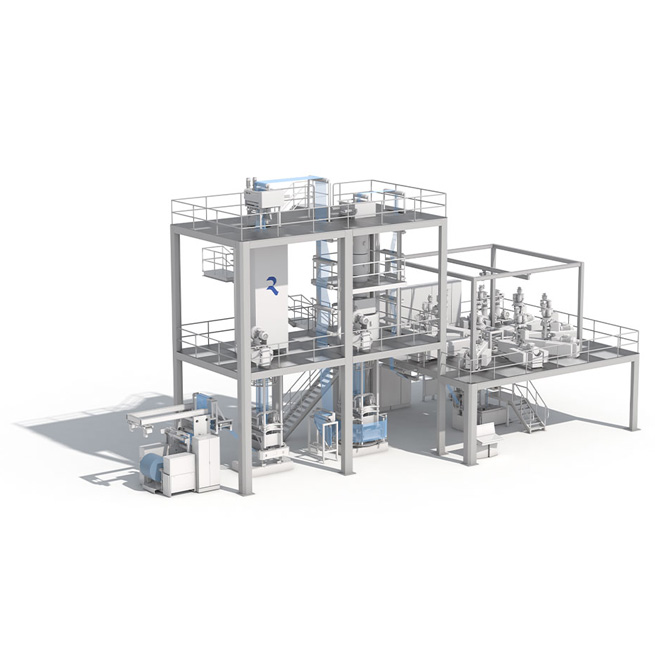

Laboratory trials and production runs for narrow layflat widths.

Test under real conditions and efficiently produce small order volumes – both on the same line. With our EVO Micro, you can run economical tests with maximum resource efficiency and results that are 100% transferable to large industrial lines. At the same time, you can also flexibly serve small orders for narrow films that are not profitable on large high-performance systems with complex start-up processes. Profit from short product changes.

EVO Micro: Perfect for you if you

- develop new recipes and processes in-house.

- want to run tests efficiently but under transferable conditions.

- need flexibility and want to efficiently handle small order volumes with frequent product changes.

Efficient research and development

Would you like to regularly develop your film recipes or production processes without disrupting your operations? Then invest in an EVO Micro blown film line. Small throughputs, low energy consumption and a small footprint make it the ideal line for research and development. Run your trials with low raw material consumption parallel to the actual production and independent of the R&D capacities of external suppliers. The scalability to large high-performance lines is unique.

Since our EVO Micro lines have the same equipment as our “big” EVOs, they can also be used for the production of narrow layflat widths from 300 – 1000 millimeters. The line is thus ideally suited as a flexible and efficient supplement to large blown film lines.

Compostable film made from renewable raw materials.

The market for sustainable films is growing steadily. Process biopolymers from renewable raw materials for a wide range of applications – from simple garbage bags to elaborate barrier packaging. A further advantage: after use, they are compostable. With EVO Bio you can easily and flexibly produce sustainable products for future market needs. Our plants are also suitable for the use of conventional raw materials.

EVO Bio: Perfect for you if you

- want to benefit from the growing market for sustainable packaging.

- want to make a contribution to the environmentally friendly use of plastics.

- want to flexibly process conventional and biological raw materials.

Special applications on flexible lines

Biopolymers and flexibility – they are not mutually exclusive. Our bio lines are based on our standard EVO blown film technology, which we specifically adapt for the processing of biopolymers. Among other things, biopolymers have a lower thermal conductivity, which requires an increased cooling capacity.

The extrusion section is therefore adapted to the increased material requirements in order to meet the highest performance and quality standards. At the same time, you retain full EVO flexibility and can switch between conventional and biological raw materials depending on market demand.

Large films, low material consumption.

In agriculture, size counts: with EVO Agriculture, you can produce films with a circumference of up to 24 meters – for example for use as mulch or silage cover films for best crop yields. Thanks to its multi-layer structure, you save material while at the same time achieving outstanding product properties.

EVO Agriculture: Perfect for you if you

- want to flexibly produce different film dimensions and applications on the same line.

- are looking for high functionality and performance with up to 7 layers.

- want to significantly reduce your material consumption.

High-performance multi-layer films in XXL format? No problem!

They have long been standard in the production of food packaging: multilayer films achieve a wide range of functionalities, such as special barrier properties. With EVO Agriculture Technology, we now also offer configurations with up to 7 film layers especially for the production of agricultural film. This allows you to distribute special additives specifically for your application over several and thinner film layers. The raw material requirement is reduced – the product properties are retained.

Maximum transparency through rapid cooling.

With EVO Aqua Cool you produce highly transparent film thanks to the quick water cooling effect, as the crystallization of the melt is strongly inhibited or even prevented. Further benefits: high gloss, extreme puncture and tear resistance as well as best thermoforming properties.

EVO Aqua Cool: Perfect for you if you

- attach importance to highest optical film properties.

- want to produce particularly robust and at the same time thermo-formable film.

- want to serve special applications in the food or medical sector.

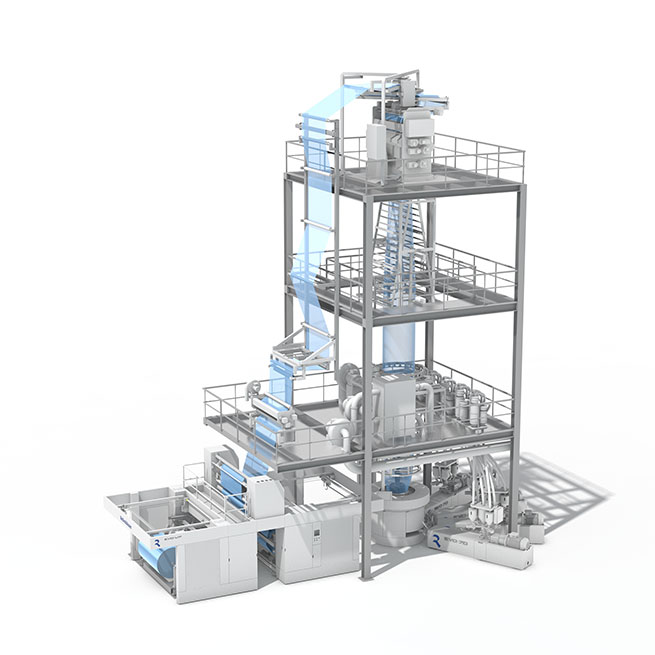

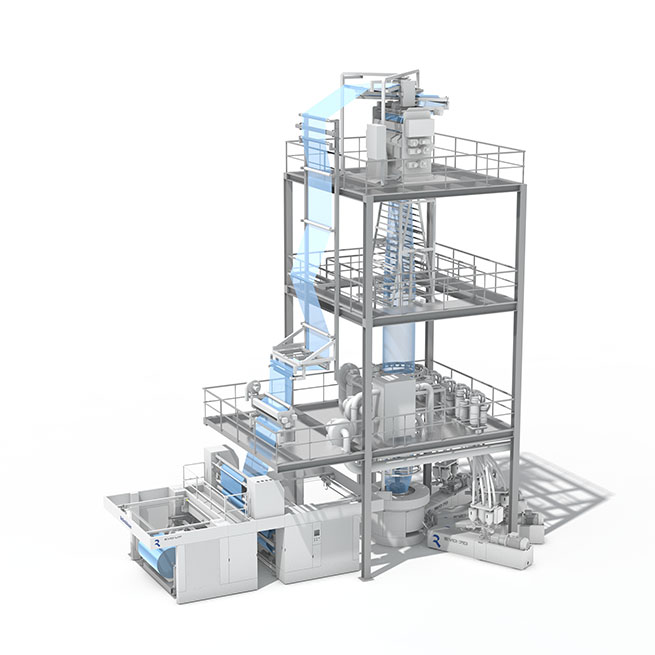

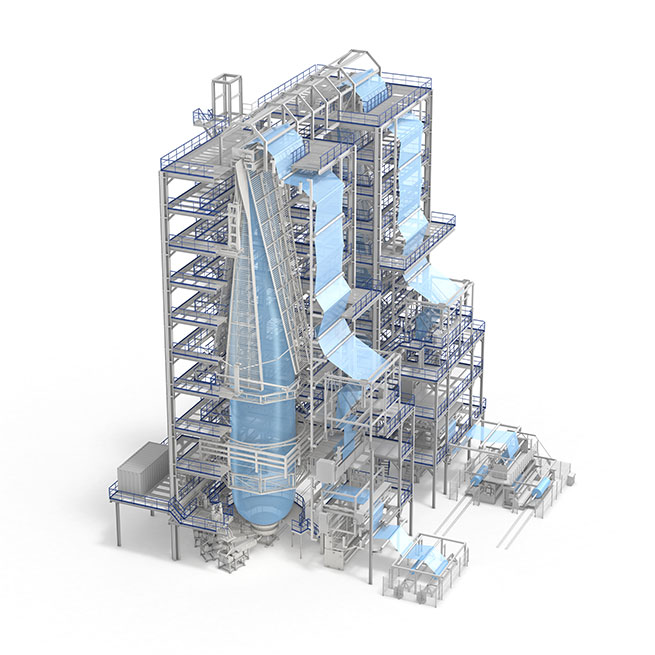

Blown film the other way around

What is the difference between conventional blown film lines and EVO Aqua Cool? Following the force of gravity of water, the extrusion direction is reversed – vertically from top to bottom. The film tube is inflated to the desired diameter and then quickly cooled down by water running down the bubble, thus creating the special optical and mechanical film properties. The water is then removed from the film with the help of negative pressure (vacuum). Our optional Ultra Flat or Ultra Stretch features allow you to optimize stiffness, barrier function or flatness during further processing – without compromising transparency and formability.

Biaxial-oriented film in one operation.

By blowing the bubble multiple times we achieve a simultaneously biaxially oriented and annealed blown film where you can achieve very special properties for your end product – all within one production process. With our Multi Bubble technology you benefit from decades of development work for the optimal stretching of thermoplastic polymers – for the highest optical and mechanical requirements. This enables you to achieve outstanding transparency, gloss, puncture resistance, seal ability and adjustable shrinkage properties.

EVO Multi Bubble: Perfect for you if you…

- want special functions and high film performance.

- value a perfectly sophisticated process.

- want to significantly reduce your material consumption.

High-performance films for food packaging

The requirements are particularly high in the food sector. Use EVO Multi Bubble to produce robust and highly transparent shrink packages with barrier function – for example for meat or dairy products. Thanks to its high puncture resistance, you also save material because you can use thinner film. Gain full control over the properties of your polymers and produce flexibly, depending on your application requirements.

Highest output rates with best film quality.

The EVO FFS line is an EVO blown film line specially developed for form-fill-seal sack applications. High output rates coupled with top film quality are often the key to success, especially on this tough competitive market. Our range of cooling systems, from Standard to Premium, offer-customized solutions for every requirement with above-average performance in all cases. A flexible line design offers both inline and offline solutions.

EVO FFS: Ideal for you if you are looking for

- higher output and therefore higher profitability.

- an operator-friendly system with a reliable production process.

- a flexible system configuration.

EVO FFS Lines – customized solutions for all form-fill-seal sack applications

All EVO FFS lines are equipped with proven EVO extruders and EVO blown-film die heads for optimized melt quality at very low melt temperatures. But that’s not all. We offer two different cooling systems with the EVO FFS lines to obtain top film quality.