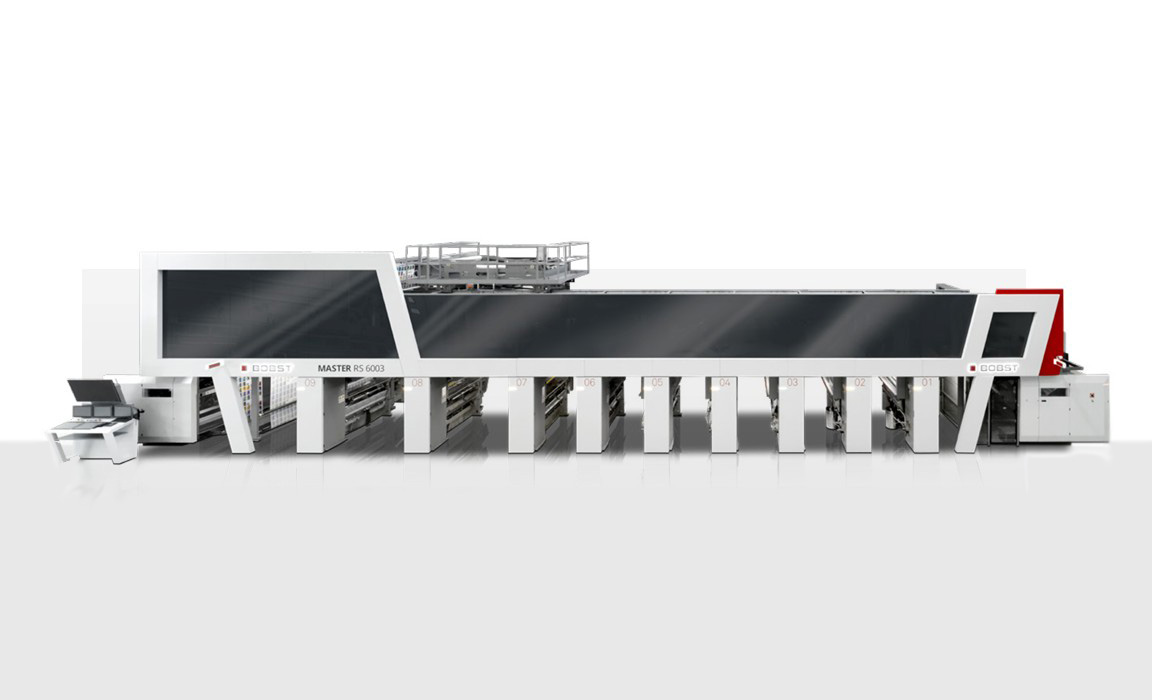

Gravure Printing

Superior print quality and consistent performance

- No compromise. High quality printing and speed combined at the same time. Printing on a wide range of materials including new eco-friendly substrates.

- Easy web handling and very precise web tension control from the unwinder to the rewinder. No wrinkles even with critical/heat sensitive/stretchable substrates

- Precise and uniform ink distribution system solutions to best fit application requirements and use of local ink varieties:

- motorized inking roller (MPI)

- idle inking roller (HSM)

- Enhanced BOBST viscosity control system with ink cooling device for outstanding stability of the printing process.

- BOBST supplies and integrates all required auxiliary equipment.

Advanced sustainability and cost savings

- Reduced waste through short web path, register pre-setting and minimum volume of ink in circulation

- Total Automatic Pre-register Setting (TAPS) for fast machine set-up and minimum waste independent of the press operator skills available as option

- Integrated Registron® register control for very fast and precise register correction

- Highly efficient Twin Flow dryers with double airflow and dedicated ventilation systems

- Fully automatic bi-directional reel splice at machine production speed. Winders energy recovery solution

- Lower Explosion Limit (LEL) system reducing emissions into the atmosphere available as option.

Automated and connected

- Exclusive automation features ensuring process repeatability and required productivity

- BOBST SPHERE Human Machine Interface, with common style and usability across all BOBST equipment

- Connectivity features for full production and quality control:

- Connectivity to enable remote access to production and process data

- Fast troubleshooting process minimizing breakdowns

- High level of security and protection for solving issues online without a technical intervention on site.

Advanced customer experience at Bobst Changzhou’s facility

- Print demonstrations or printing of customer jobs

- Analysis of job production data such as solvent retention and quality control

Training classes in Chinese and in English by expert operators.

Unique solutions for excellent performance and print quality across flexible substrates and applications

- Very precise web handling from unwinder to the rewinder for a wide range of flexible materials, including the new eco-friendly substrates

- Performance at speed with both solvent- and water-based inks. Suitable for oneECG Extended Color Gamut printing

- Choice of inking systems. High Speed Meter (HSM) roller system or Multi-Purpose Inking (MPI) system suited where the use of market-specific varieties of inks is common

- Trolley types to best fit specific production requirements

- Complementary operations can be added inline with printing.

Sustainability, ease of operation and fast time-to-market

- Higher uptime from automation, fast and easy job sequences, advanced ergonomics and press layout

- Waste and energy savings from:

- TAPS system for automatic pre-register setting and fast register correction from ELS and Registron® register control integration

- Efficiency of Twin Flow dryers with double airflow and dedicated ventilation systems

- Fully automatic bi-directional reel splice at machine production speed. Winders energy recovery solution

- Optimum accessibility for web threading, cleaning and maintenance operations.

Exclusive automation and connectivity

- Different levels of automation, all ensuring process repeatability and required productivity

- BOBST SPHERE Human Machine Interface, with common style and usability across all BOBST equipment, enabling:

- Digital logging of machine parameters for each produced reel

- Downtime tracking and waste management

- Maintenance programming

- Connectivity features for full production and quality control and for informed decision making. Monitoring Apps and BOBST Connect available for full remote connectivity and support.